Hydrogen Transition #1

There has been a lot of dialogue and discussion lately on transitioning to hydrogen from natural gas. Much of this discussion is centered on reusing

There has been a lot of dialogue and discussion lately on transitioning to hydrogen from natural gas. Much of this discussion is centered on reusing

Doing what we do best. When we are onsite we are always looking out for problems with control logic that is causing equipment problems. Here

Quality control /assurance is sometime taken for granted. After all there is a minimum level of confidence that we expect in terms of quality from

A client was evaluating a used plant for an expansion project. Of course it was advertised as a great deal, much less than a new

Another recent client problem we were able to troubleshoot successfully dealt with a TEG dehydration system. The lean TEG out of the regenerator (reboiler) never

We performed an investigation for a client who had recently had a serious incident. Their wells flow through a sand separator before going through a

About a year ago we did a plant evaluation for a client. One of the major findings was that to match the data we had

It’s amazing how some problems keep repeating themselves. That’s where the RCE experience and expertise comes into play for our clients. Recently a gas plant

Here at RCE, some times we’re so good at our job that we cost ourselves business. We had been engaged in designing a new Trans-Mix

The RCE “rule” is that you must have a pre-alarm before a shutdown. The reason for this “rule” is that it is imperative to give

Inadvertent valve opening is a scenario that comes up time and time again during process hazards reviews. An example of why we spend the time

Sometimes operations have to make adjustments to account for issues with equipment performance. One recent example was a GSP type of gas plant that had

Garbage in equals garbage out. That’s an old saying but it still applies to many things. In this case it relates to trying to define

A gas plant was utilizing all their residue compressors to process 200 MMSCFD when it designed to have one as a spare. RCE engineers took

Interesting optimization finding. A gas plant was operating in what appeared to be pretty good shape. Ethane recoveries were right around 90%, which are not

A new plant was started up recently and instead of getting ethane recoveries in the mid 90% range as expected, recoveries were in the mid

A few months after start-up a plant was having problems with high refrigeration condensing pressure. The first step was to get an analysis of their

We recently visited a gas plant whose ethane recoveries were suffering. The plant personnel said they knew what the problem was and that was lack

How does this get designed this way? How does this get through multiple reviews including PHA’s without being noticed? How does this get built without

Client received EPC bids from two contractors. While the client was reviewing commercial terms, schedule, etc. RCE performed a technical review. RCE pointed out to

Our client was notified by the NGL pipeline that they were going to be penalized for excessive methane (C1) in the NGL’s that were being

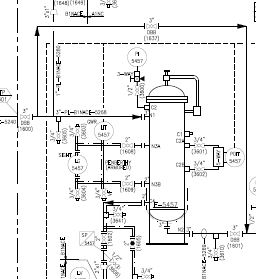

RCE was involved with the design of a small refrigeration gas plant. In the span of a single week, RCE through its comprehensive review of

During a plant visit, RCE engineers noticed that the Refrigeration Economizer was operating at a pressure very close to that of the Refrigeration Accumulator. The

Lawsuit against a pipeline company alleging that delivered gas to the facility was above the 7 lbs H2O/MMSCF specification. This caused the facilities regulators to

RCE was supporting it’s client as owner’s process engineer on a large project. During early P&ID reviews RCE noted to the EPC Contractor that the

RCE engineers visited a new client’s plant that was originally built as a Residue Recycle (RR) process around 30 years ago. At some point the

During start-up, the column was flooding and carry-over was evident. The latent heat of evaporation of the liquids carried over caused severe problems with maintaining

Prolonged bypassing of the expander in JT mode led to thermal stresses that caused a plate-fin heat exchanger to fail (cracked). Rather than installing the

So I recently got into an web posting discussion that ended up amusing me. Someone posted a question about converting Btu/SCF to Btu/lb. There were

Performed preliminary engineering and cost estimating for expanding an existing 55 MMSCFD cryogenic gas plant to 65 MMSCFD and improving overall liquids recoveries. The new